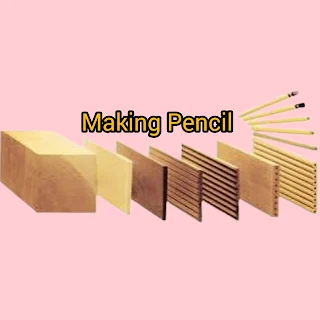

Introduction:

Pencils, those ubiquitous writing instruments found in classrooms, offices, and art studios worldwide, have a fascinating journey from raw materials to the finished product. Join us as we delve into the intricate process of pencil creation, exploring each step that transforms humble materials into the versatile tools we use every day.

1. **Harvesting the Wood:**

The journey begins in forests where cedar trees, prized for their durability and smooth texture, are carefully selected and harvested. Sustainable practices are often employed to ensure a responsible use of natural resources.

2. **Cutting and Drying:**

The harvested cedar is then cut into pencil-sized slats. These slats undergo a meticulous drying process, crucial for reducing moisture content and preventing warping or cracking in the subsequent stages of production.

3. **Clay and Graphite Application:**

Next, the dried slats are coated with a unique mixture of clay and graphite. The proportions of these components determine the pencil's hardness or softness. The application of this mixture is a critical step, as it influences the writing characteristics of the pencil.

4. **Shaping the Pencil:**

Once coated, the slats are shaped into the familiar cylindrical form. Precision is key during this step to ensure uniformity and consistency in the final product. Some manufacturers use a hexagonal shape for added grip, while others prefer the classic round design.

5. **Wooden Casing:**

To encase the graphite core, a wooden casing is applied. This casing not only provides structural support but also serves as a canvas for branding and decoration. The choice of wood and its quality impact the overall aesthetics and durability of the pencil.

6. **Painting and Imprinting:**

Pencils receive a coat of paint for visual appeal and branding. Manufacturers imprint essential details, such as the pencil's hardness and brand name. This step adds the finishing touches to the external appearance of the pencil.

7. **Quality Control:**

Rigorous quality control checks are conducted to ensure that each pencil meets the established standards. This includes assessments of wood quality, graphite alignment, and overall finish. Defective pencils are discarded, maintaining the integrity of the final product.

8. **Packaging:**

The last step involves carefully packaging the pencils for distribution. Whether in simple cardboard sleeves or elaborate display cases, packaging protects the pencils during transit and provides essential information to consumers.

Conclusion:

From the forest to your hand, the creation of pencils involves a meticulous and fascinating process. Each step contributes to the functionality, durability, and aesthetic appeal of these everyday tools. The next time you pick up a pencil, take a moment to appreciate the craftsmanship and journey behind this seemingly simple writing instrument.

Back To Homepage

Read more⬇

Free Download Princess and the Magic Dragon pdf. Kindly click below.